Lithium is vital for electric vehicles and grid energy storage, but traditional extraction from briny water uses huge evaporation ponds that take months to years, large land areas, and massive water usage. Researchers at Princeton University have introduced a string-based extraction technique that could dramatically reduce land, time, and environmental impacts compared to conventional methods. Princeton University Lithium on a String what a Concept!!

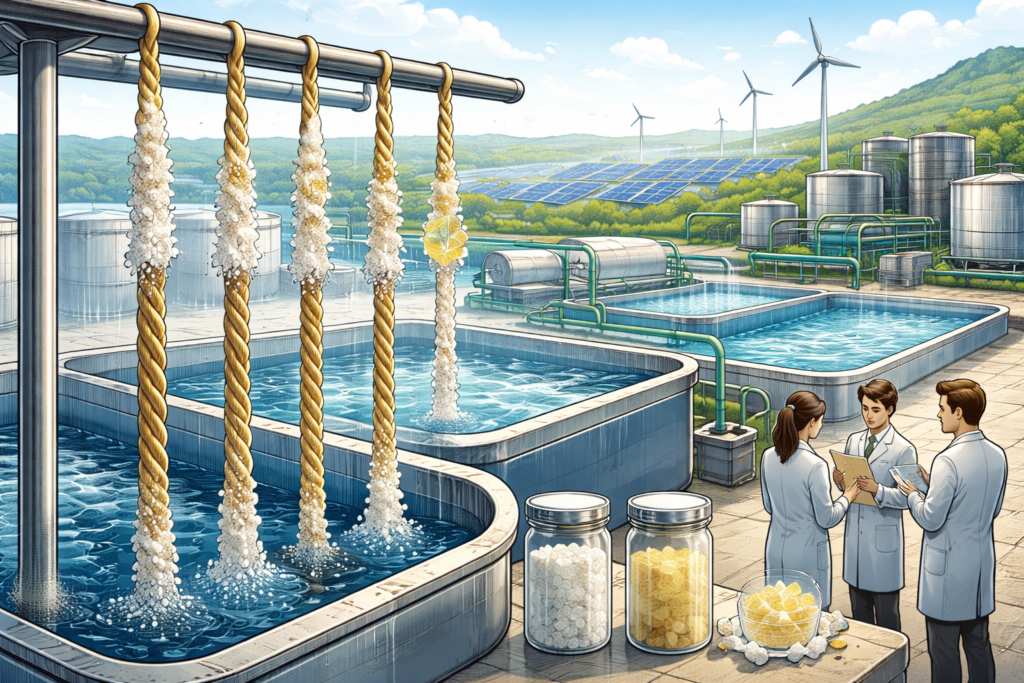

How the String Technology Works

The technique uses porous fibers twisted into strings with a water-loving core and water-repelling surface. When dipped into lithium-rich brine:

- Water travels up the string by capillary action

- Water evaporates quickly, concentrating salts

- Lithium salts and sodium salts crystallize in different regions

- Salt crystals can be harvested directly from the strings

This method does not require additional chemicals, reducing water use and operating energy. Princeton University

Why This Matters

Compared to traditional lithium evaporation ponds, the Princeton technique could:

- Reduce land use by over 90%

- Speed up extraction by 20×

- Produce initial lithium in less than one month

- Bring previously uneconomical sources into play

Potential sources include oilfield brines, geothermal brines, and low-grade salt formations — greatly expanding the usable lithium resource base. Princeton University

Real-World Industrial Advances in Lithium Extraction

Although Princeton’s string method is still in the scaling stage, there are major real-world developments in similar and complementary lithium extraction technologies:

1. Direct Lithium Extraction (DLE) at Commercial Scale

Modern DLE technologies, unlike traditional evaporation, can extract lithium from brine with higher efficiency and lower environmental impact. Cleantech Group+1

- Standard Lithium and Equinor secured a $225 million U.S. Department of Energy grant to build one of the first commercial DLE facilities in Arkansas, expected to produce ~45,000 tonnes of lithium carbonate per year starting around 2028. Reuters

- EnergyX, backed by General Motors, is developing DLE technology and acquiring lithium-rich acreage in the U.S., aiming to build lithium refining capacity using advanced extraction tech. Reuters

Companies such as Summit Nanotech and SunResin are also piloting DLE technologies globally, with some commercial operations already underway in China and South America. Cleantech Group

2. Sustainable and Zero-Carbon Extraction

Other industry players like Vulcan Energy Resources are pursuing zero-carbon lithium extraction by using geothermal heat and direct extraction methods that eliminate evaporation ponds entirely. Wikipedia

Environmental and Energy Transition Benefits

New extraction methods including the string technology and advanced DLE could significantly reduce:

- Water consumption compared to conventional evaporation

- Land disturbance and ecosystem disruption

- Energy use and carbon footprint per tonne of lithium produced

This supports broader energy transition goals by enabling cleaner battery supply chains for electric vehicles and stationary energy storage systems. Accelerating sustainable lithium extraction also ties directly into global environmental targets such as the United Nations SDG 7 (Affordable and Clean Energy) and SDG 12 (Responsible Consumption and Production).

Challenges Ahead

While these innovations are promising, they face barriers:

- Commercial scaling from lab to industrial capacity

- Capital and infrastructure needs for pilot and first-of-a-kind facilities

- Regulatory and environmental oversight to ensure responsible brine handling

Nevertheless, with demand for lithium expected to grow sharply through the 2030s, these technologies offer transformative potential.

Princeton’s string-based lithium extraction demonstrates how fundamental physics (capillary action + evaporation) can be harnessed for cleaner, faster lithium production. Combined with the growing wave of Direct Lithium Extraction (DLE) and zero-carbon processes, the future of lithium supply looks more efficient and environmentally responsible.

This is not just a lab experiment — commercial projects backed by governments and industry are already bringing next-generation extraction closer to reality.

External References

- Princeton research overview on lithium extraction strings — Princeton University Princeton University

- Growing global development of DLE technology — Cleantech Group Cleantech Group

- Standard Lithium & Equinor US project — Reuters Reuters

- EnergyX lithium technology & land acquisition — Reuters Reuters

- Zero-carbon lithium production — Vulcan Energy Resources Wikipedia

- Read our Article on DLE