A Practical Path to Circular Water & Energy Solutions

Industrial wastewater management and lithium recovery are emerging as two of the most pressing environmental challenges worldwide. As water scarcity, battery demand, and environmental compliance tighten, capillary action based evaporation is gaining attention as a low-energy, scalable, and circular solution.

This approach aligns strongly with global sustainability goals and is now being explored locally in Pakistan as well.

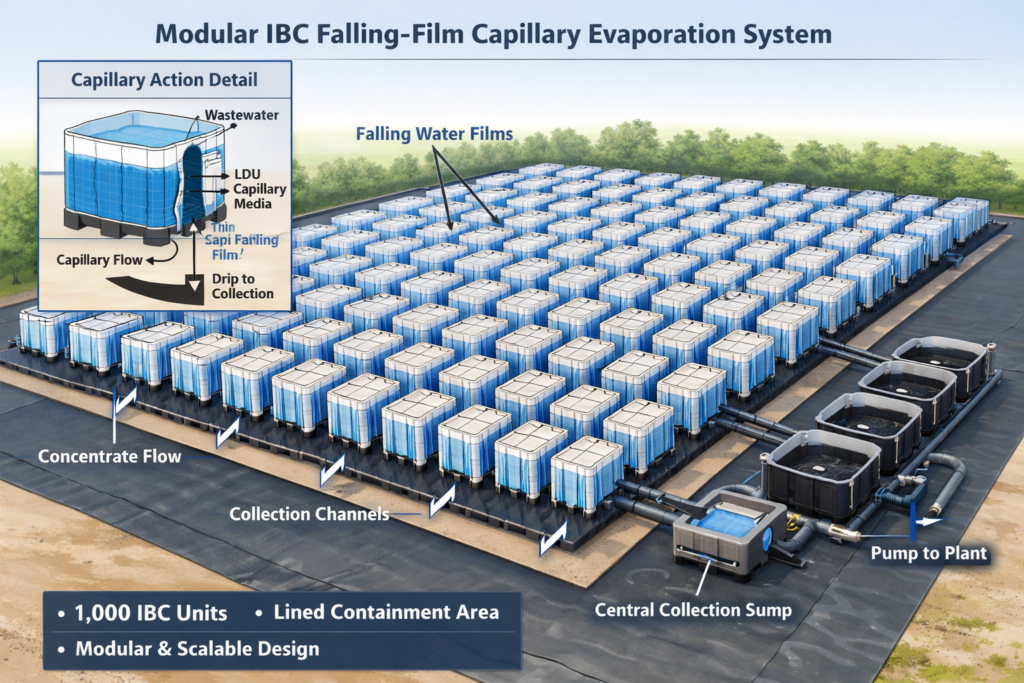

Capillary Action Evaporation: How It Works

Capillary action evaporation uses engineered porous or fibrous media to spread wastewater into ultra-thin films. This dramatically increases surface area, allowing faster evaporation with minimal energy input, unlike conventional deep evaporation ponds or thermal evaporators.

Key advantages include:

- Low CAPEX and near-zero OPEX

- Reduced land footprint

- Minimal drift and aerosol losses, saves mist overspray in sensitive regions

- Compatibility with brackish, saline, and industrial wastewater

This makes it particularly suitable for wastewater management for fertilizer, chemical, brine, municipal waste, mining, and power plants operating in land stressed regions.

Lithium Recovery Through Evaporative Concentration

Globally, lithium recovery increasingly relies on controlled evaporation to concentrate lithium-rich brines before extraction.

Capillary-assisted evaporation can:

- Accelerate lithium concentration without large ponds

- Reduce water loss and environmental impact

- Enable modular, containerized recovery systems

This concept complements Direct Lithium Extraction (DLE) technologies by reducing brine volumes upfront, improving overall recovery economics.

Fatima Fertilizer’s Capillary Evaporation Initiative

At Fatima Fertilizer, Sadiqabad-PK Plant, engineers are actively evaluating capillary action based evaporation as a novel solution to address wastewater evaporation challenges at plant sites.

The initiative focuses on:

- Reducing dependency on conventional evaporation ponds and reducing land footprint

- Improving environmental compliance

- Exploring circular reuse of evaporated residues and utilization of waste valorization themes

- Developing a scalable, homegrown engineering solution

This work reflects a shift from imported, energy-intensive systems toward locally engineered, climate appropriate innovation.

🔗 Reference: See a LinkedIn Post

Global Practices & Industry Adoption

Internationally, similar principles are being explored by:

- Mining firms in Chile and Argentina for lithium brine management

- Zero-Liquid-Discharge (ZLD) solution providers in the Middle East

- Startups using capillary media for produced water evaporation in oil & gas

- Research institutes developing passive evaporation enhancers for desalination brines

These efforts confirm that passive evaporation enhancement is no longer experimental—it is becoming an industrial tool.

Connecting to a Broader Environmental Agenda

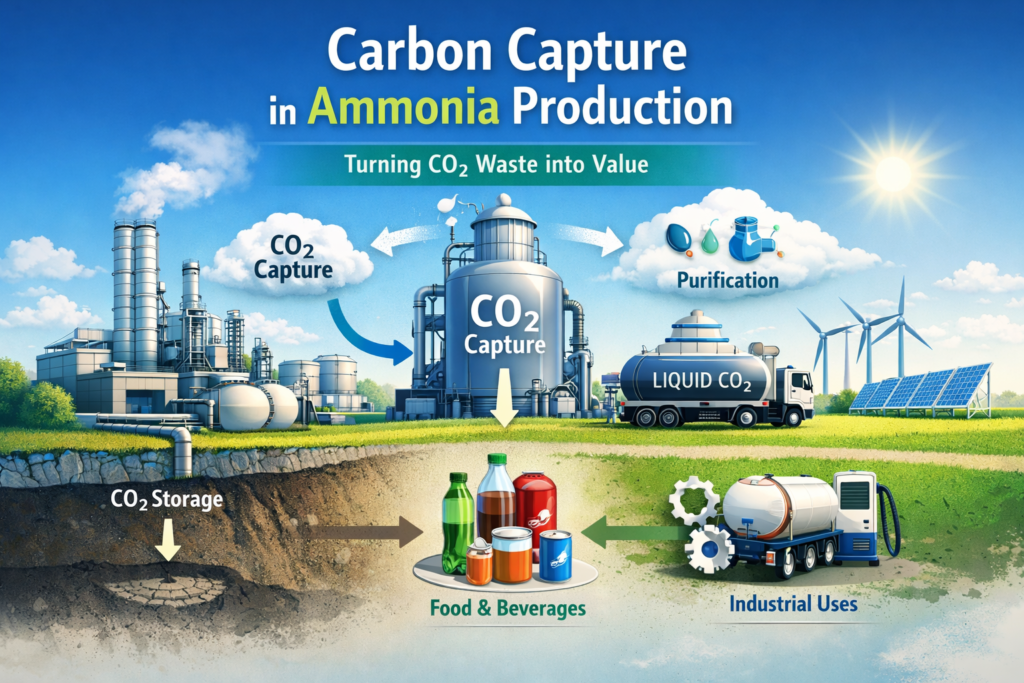

Capillary evaporation and lithium recovery sit within a much larger sustainability framework that includes:

Technology & Infrastructure

- Carbon Capture and Storage (CCUS) for industrial emissions

- Long-duration energy storage for renewable reliability

- Hydrogen transport for hard-to-electrify sectors

- Low-carbon construction and smart buildings

- Green data centers and digital carbon reduction

Policy & Economic Strategies

- Mandatory ESG reporting to prevent greenwashing

- Phasing out harmful products through choice-editing policies

- Incentives for green investment and clean manufacturing

- Integration of natural climate solutions into national policy

- Strong advocacy for circular economy models

Community-Level Action

- Community-owned renewable energy projects

- Waste-based art, fashion, and urban installations

- Rain gardens and native landscaping for water resilience

- Local food hubs, composting, and school garden programs

Why This Matters

Solutions like capillary action evaporation demonstrate that:

- Sustainability does not always require high energy or high cost

- Local engineering talent can solve global problems

- Circular economy principles can be applied at plant scale

- Environmental compliance and operational efficiency can align

As industries face tighter regulations and rising resource costs, simple physics-based innovations may prove more powerful than complex systems.

The future of environmental progress lies not only in breakthrough technologies but in smart adaptation of natural processes, engineered thoughtfully for industrial reality.

Capillary evaporation is one such idea; quiet, practical, and potentially transformative.

Read more from Princeton University

Read further on our recent article on EnvironmentAgenda.com

Very informative ✅👍

Thanks