Industry Practices and a Look at CO₂ Recovery

Carbon capture has become an increasingly important topic for energy-intensive industries. Among these, ammonia and fertilizer plants play a critical role because carbon dioxide (CO₂) is an inherent by-product of their production processes. While modern plants are being designed with advanced capture technologies, many existing facilities continue to manage CO₂ through process-integrated recovery and utilization.

This article explores how carbon capture typically works in ammonia plants and highlights, at a high level, how conventional ammonia plants recover and utilizes CO₂ as part of its operations.

Why Ammonia Plants Generate CO₂

Ammonia is commonly produced using natural gas steam reforming, where methane is converted into hydrogen. During this process, carbon dioxide is generated and must be removed before ammonia synthesis can take place.

As a result, CO₂ separation is already embedded in ammonia production. However, the fate of this CO₂ whether it is vented, reused, or further processed depends largely on plant design, age, and technology choices.

For an overview of ammonia production and emissions, see:

🔗 https://www.iea.org/reports/ammonia-technology-roadmap

Carbon Capture in Legacy Ammonia Technologies

Many ammonia plants around the world operate using legacy process technologies that were designed primarily for reliability and output, rather than deep carbon mitigation. These technologies typically:

- Remove CO₂ from synthesis gas for process reasons

- Do not include full carbon capture and storage (CCS) by default

- May vent a portion of CO₂, particularly from combustion and utility systems

Nevertheless, even in such plants, opportunities exist to recover and utilize CO₂, especially where there is downstream demand.

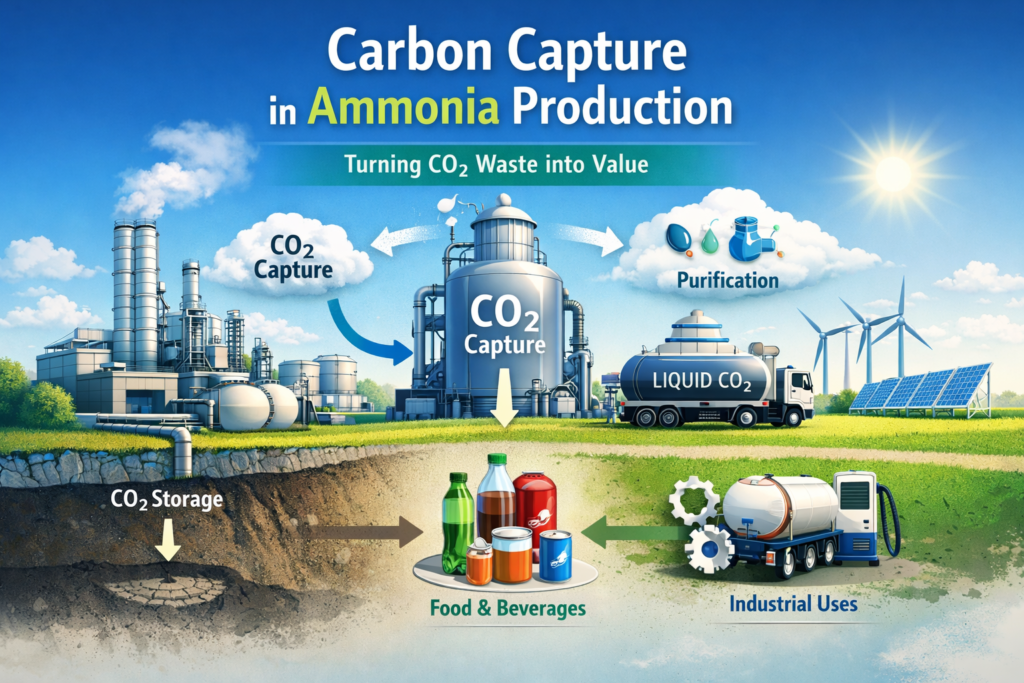

CO₂ Recovery and Utilization: An Industry Practice

Instead of venting all separated CO₂, some fertilizer complexes integrate liquid CO₂ (LCO₂) plants. These units:

- Purify process CO₂

- Compress and liquefy it

- Supply CO₂ for industrial or food-grade applications

This approach does not represent full CCS, but it does:

- Reduce direct venting

- Improve resource efficiency

- Convert a process by-product into a commercial product

More on CO₂ utilization pathways can be found here:

🔗 https://www.globalccsinstitute.com/carbon-capture-and-storage/utilisation/

Fatima Fertilizer’s CO₂ Recovery Initiative (Sadiqabad)

At its Sadiqabad production complex, Fatima Fertilizer operates an integrated fertilizer facility that includes ammonia production and downstream units. As part of its operations, the company runs a liquid CO₂ recovery plant.

In general terms:

- CO₂ generated during ammonia processing is captured from process streams

- The gas is purified and liquefied

- The resulting liquid CO₂ is supplied to industrial users, including the food and beverage sector

- The CO₂ is food-grade and halal-certified, enabling its use in applications such as beverage carbonation

This initiative reflects a utilization-focused approach thus recovering unavoidable process CO₂ and placing it into productive use, rather than releasing it directly to the atmosphere.

Company overview (external reference):

🔗 https://www.fatima-group.com/fertilizer/fatima-fertilizer/

Carbon Capture vs. Carbon Utilization

It is important to distinguish between:

- Carbon Capture and Storage (CCS): capturing CO₂ for long-term storage to reduce net emissions

- Carbon Capture and Utilization (CCU): capturing CO₂ and using it in products or industrial processes

CO₂ recovery for food and industrial use falls under CCU, which offers operational and economic benefits, although it does not eliminate emissions entirely. Still, CCU is widely recognized as a practical transition pathway, especially for existing industrial assets.

Why This Matters for Sustainability

For fertilizer and chemical producers, CO₂ recovery initiatives:

- Demonstrate responsible resource management

- Support circular economy principles

- Contribute to incremental emissions reduction

- Align with broader ESG and sustainability reporting goals

While deeper decarbonization will require additional technologies over time, process-integrated CO₂ recovery remains a relevant and realistic step for many operating plants.

Carbon capture in ammonia plants takes many forms, ranging from full CCS systems to integrated CO₂ recovery and utilization. In the case of Fatima Fertilizer’s Sadiqabad complex, CO₂ recovery through a liquid CO₂ plant represents an example of how existing facilities can responsibly manage process emissions while creating value.

As the fertilizer industry continues its transition toward lower-carbon production, such initiatives highlight the role of practical, plant-level actions alongside future large-scale decarbonization solutions.